Your Custom Nutraceutical Capsule Manufacturer

We look forward to partnering with you to bring your capsule supplement ideas to life.

Plot No. 10 to 26, Sky Industries, Near Krishna Park Industries, Lindiad, Surat - 394530, Gujarat, India.

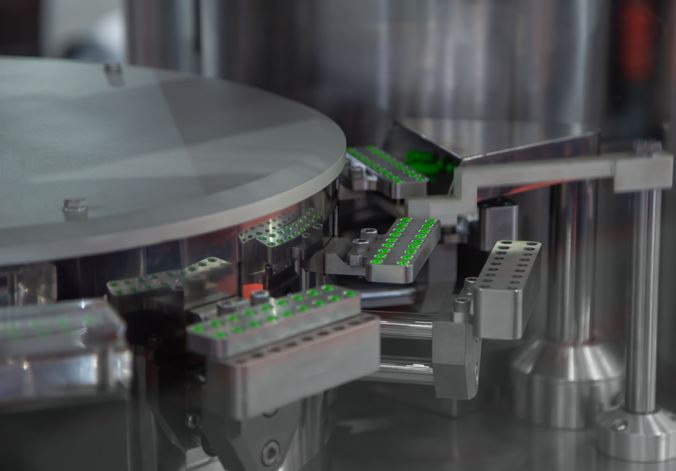

Welcome to Nutricore's state-of-the-art capsule nutraceutical manufacturing section.

Nutricore is a leading provider of third-party manufacturing solutions for capsules. Our dedication to quality, innovation, and reliability sets us apart as the ideal partner for businesses seeking to introduce their capsule products to the market. Leveraging our advanced facilities, skilled team, and efficient processes, we guarantee a smooth and prosperous journey in capsule manufacturing.

Nutraceutical blending begins with precise weighing and measuring; ingredients are placed in a vessel for uniform distribution, ensuring consistency.

As soon as your formula has been blended, it is filled with capsule shells. We can encapsulate it in gelatin and vegetable capsule shells.

Post-filling capsules undergo thorough inspection for efficacy and safety. Optional polishing depends on equipment, formulation and desired appearance

Our quality assurance system checks identity, potency, micro, and heavy metals after capsules are manufactured.

Whether you need us to manufacture your nutraceutical capsule formula—from sourcing each ingredient to performing a post-encapsulation inspection—we can do it all for you at the most affordable price.

We are able to help you formulate a new product for your target audience or discuss with you how to properly scale your manufacturing. As your partner, it is our responsibility to ensure your capsule manufacturing success for a long time to come.

Our team can blend and encapsulate your formula with little to no effort. This makes capsules a very reliable and widely accepted method of encapsulating nutraceutical formulas.

The task involves selecting and weighing raw materials such as active ingredients, fillers, and capsule shells, in accordance with the formulation requirements.

Blend weighed ingredients in a blending vessel using methods like tumble blending or high-shear mixing to achieve a uniform mixture.

Transfer the blended mixture to an encapsulation machine, where capsules are filled with the nutraceutical blend, ensuring consistent dosages.

The task involves final quality control checks, including weight and content uniformity, inspection of capsules for defects, and proper labeling for distribution.